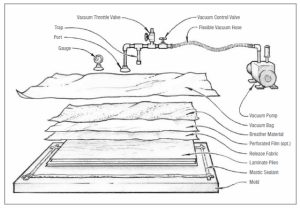

By Rachael Geerts – GBI Composites Materials Engineer Featured image (above): A typical vacuum bagging setup. What is vacuum bagging? Vacuum bagging is when a composite that is laid up and wet out by hand is then put under vacuum to compact the laminate and force out excess epoxy. Vacuum bagging has been a choice […]