Building a Lightweight Aerodynamic Caravan

by Robin Benjamin

The Plystream aerodynamic caravan camper simply couldn’t exist if not for epoxy. It’s as simple as that. No other wood glue would have the strength to hold the curved panels in place, keep the structure waterproof, and ensure that it doesn’t simply fall apart during use.

The Plystream is made from a wooden framework fixed to a standard 2.5 m (8.2′) trailer and then clad inside and out with 3 mm exterior-grade Okoume plywood. Between the sheets, XPS foam board is used for insulation. The only screws used in the construction are those used to screw the framework together. Once the frame is completed, every single panel is epoxied onto the frame.

Initially the frame is very flimsy, but as more and more wood is added, it gets stronger and stronger. Once the panels are epoxied on, the strength increases again. In the end, despite its extremely light construction, it is extremely rigid.

The Framework

The first step is to make a jig for the 30 corner beams, which create the rounded corners of the Plystream. I made two jigs so I could make two beams each day. Each corner beam was made up of six pieces of plywood epoxied into a curve. This helped to minimize springback when they were removed from the jig.

The Wall Panels

Once the framework is complete, the curved panels are fitted to the inside of the framework. It is not too hard to bend 3 mm plywood around this radius, so long as the plywood is cut across the grain and not along it, of course. As the larger flat panels have not yet been fitted, there is plenty of space to use clamps to hold the panels in place while the epoxy cures.

Vertical Corner Panels

The vertical corner panels are relatively easy to glue in place, but the top corner ones are more challenging. I started with the inner ones. They proved quite tricky. To get the inside corner panels to fit the space well, it was necessary to shape the center piece like an arrow. In fact, on yachts with teak decks, often the planks are ‘joggled’ into the ‘King plank’ (the center plank of a deck) in this fashion. I had planned on using four pieces to get the shape, but ultimately three worked better and simplified the design. The Plystream is more challenging to build than most of our designs, but still well within reach if you can follow instructions.

Outer Corner Panels

When it came to creating the outer corner top pieces, I found that three pieces would not give the nice rounded shape I was looking for. So, I had to use four. It’s not always easy to take a two-dimensional piece and turn it into a nice curve. I knew that if the plywood would bend without breaking, the strength of the epoxy and its gap-filling properties would hold it there. After using WEST SYSTEM for over three decades, I have come to trust its strength! For the Plystream build, I used WEST SYSTEM 105 Epoxy Resin® with 205 Fast Hardener® and 406 Colloidal Silica to thicken the mix. I would thicken the epoxy to a no-sag consistency for use on vertical surfaces and to ensure any gaps would be filled.

With all the curved panels in place, it is much easier to fit than the flat ones. All in all, about 20 sheets of 3 mm plywood were used! Despite all that wood, the entire completed Plystream trailer only weighs a mere 300 kilos (661 lbs.)!

“Despite all that wood, the entire completed Plystream trailer only weighs a mere 300 kilos (661 lbs.)!“

The Interior

The interior is kept simple. Two single bunks convert to a spacious double bed simply by dropping in the seat bunks. Under the bunks is a massive amount of storage. A simple galley was constructed on one side at the rear. The other side was left open for storage, or perhaps for a shower at some time in the future. Of course, if you are building your own Plystream, you can fit the interior out anyway you like!

Having the door at the back means it’s easy to load it up with long items such as boats or bicycles.

To keep the Plystream as airy and light inside as possible, three opening double-glazed windows are fitted. There’s even a small, round, non-opening window fitted to the rear door. Having the door at the back means it’s easy to load it up with long items such as boats or bicycles. While I was there, I decided it would be nice to have the door in two halves.

The Exterior

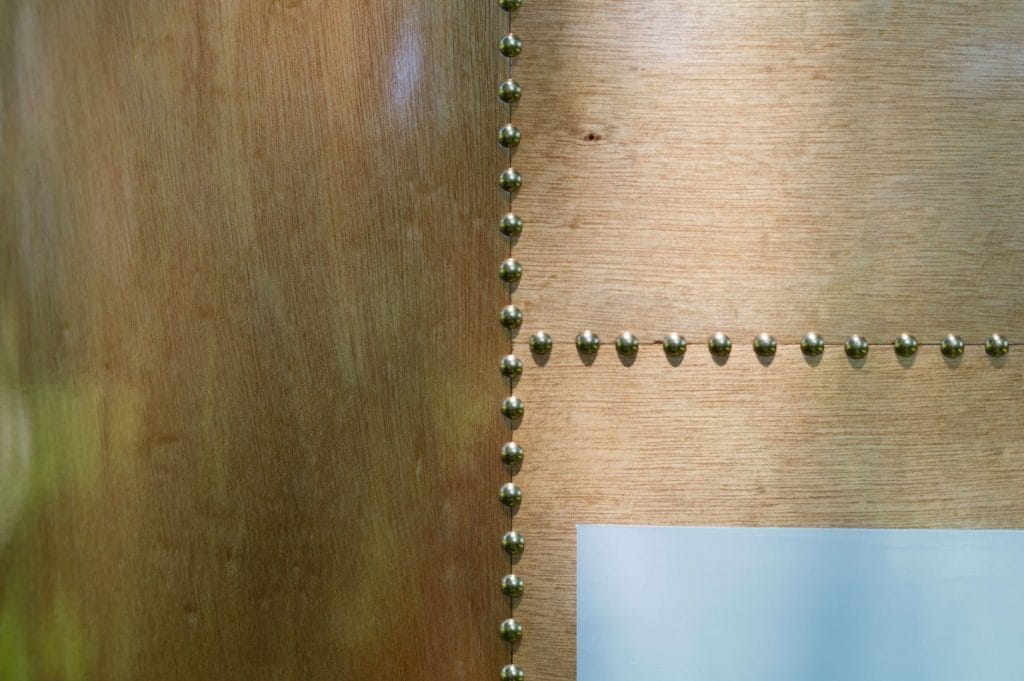

The outside of the Plystream is finished with Epifanes® yacht varnish. I created a Woodenwidget graphic on the sides using white and cream paints and fine-line masking tape. As an added feature, I incorporated no less than 2000 brass upholstery nails, mainly to disguise the joints, but also to make it look as if the Plystream is constructed using rivets!

On the road, the Plystream is a delight. Because it only weighs 300 kg (661 lbs.), you hardly even notice the weight. Even better, it is unaffected by passing trucks or side winds. This must be due to the curved sides, which make the Plystream somewhat aerodynamic. This was also born out by the fact that the fuel consumption barely increased, which came as quite a surprise.

Road Trip!

The Plystream was tested on a family holiday to the Cévennes in the south of France, where it proved a hit with young and old. We were greeted with smiles and waves and made friends everywhere we went. We drove over 1000 trouble-free kms (620 miles), and the Plystream passed all its tests with flying colors.