By Rachael Geerts – GBI Composites Materials Engineer

What is the difference between abrasion and impact? What materials hold up best against each of them? These questions often come up when talking about skid plates. Skid plates are a protective layer, typically on canoes and kayaks, that reinforces the areas of the hull most likely to suffer damage from abrasion and impact.

Abrasion is when friction wears, grinds, or rubs away a material. Impact is when a material is forcefully struck. Both of these destructive forces act on the material’s surface. The simplest way to differentiate the two is to say impact is a sudden striking force while abrasion is a rubbing force that removes material, typically over time.

It is common for boats of all types to suffer from impact and abrasion. Canoes and kayaks are dragged across rocks and gravel when we put them in and take them out of the water, and they can hit rocks or fallen trees while we’re using them. The decks of both power and sailboats experience abrasion from foot traffic (could be from street shoes with gravel stuck in the treads) or impact damage from equipment like anchors or masts. Next, we’ll look at impact and abrasion-resistant materials that can extend the life of your watercraft.

Fabrics

Kevlar®

Kevlar is a brand name for aramid fibers made by DuPont™. These synthetic fibers offer good abrasion and impact resistance as well as other structural properties. This bright yellow material is popular for applications that need a lot of abrasion or impact resistance, such as skid plates. Many builders specify Kevlar for powerboats because it resists puncture during impact.

As a fabric, Kevlar is very durable which can make it hard to cut and work with for the average do-it-yourselfer. It is also one of the more expensive reinforcement materials.

Dynel™

Dynel is a synthetic fiber made of acrylonitrile and polyvinyl chloride. Typically less expensive than Kevlar, it’s been around since the early 1950s. It remains white when wet out with epoxy.

While Dynel is a good choice for abrasion and impact resistance, it tends to float in the epoxy. When working with this material, wet it out and scrape off any excess epoxy. If there are areas where the epoxy is pooling, the fibers will float and not make good contact with the surface below. Once the epoxy has gelled or cured, you can apply more coats of epoxy to fill in the weave of the fabric. But you can also leave Dynel’s weave unfilled to provide a textured walking surface on decks.

Xynole

Xynole is also a synthetic fiber fabric. Made of very tough polyester fibers, it’s great for impact and abrasion resistance. Low-priced Xynole is an economical alternative to Kevlar. However, it’s not as strong as Kevlar and can absorb quite a bit of epoxy, resulting in heavier laminates.

Innegra™

Innegra is a fairly new reinforcement fiber by Innegra Technologies™ that is made from a low-density, high-modulus (high stiffness) multi-filament olefin yarn. It has good impact and abrasion resistance and can cost less than Kevlar. Innegra is commonly found in hybrid fabrics. This means it is woven with another reinforcement fiber such as carbon. Hybrid fabrics are priced higher as they combine the advantages of both reinforcement fibers.

Honeywell Spectra®

Honeywell Spectra is another newer reinforcement fiber that shares many of the characteristics of Innegra. These bright white fibers are made out of polyethylene and are very strong with good impact and abrasion resistance. Because of their high strength, they’re frequently used in sailboat rigging. Honeywell Spectra fabrics tend to be more expensive, so might not be as readily available as other reinforcement fabrics in retail settings.

Fiberglass

So far we have gone over some of the high-tech reinforcement fibers for abrasion and impact resistance, but let’s not underestimate the properties of fiberglass. You can use it in many applications to improve surface durability and a 4-6 oz. fiberglass layer is frequently applied on the outside of cedar strip canoes and other boats for this purpose. Fiberglass may not hold up against impact and abrasion quite as well as some of these other fabrics but it can hold its own in this application.

Additional benefits of fiberglass are that it’s relatively inexpensive, you can find it in a wide range of sizes and weights at most retail stores, and it’s generally easier to work with.

Epoxy Resins

105 Epoxy Resin

WEST SYSTEM® 105 Epoxy has been used for years to wet out the fabrics listed above. It has a higher toughness so it’s less prone to cracking than standard polyester resins. You can also modify it with additives for better abrasion resistance.

G/flex® Toughened Epoxies

G/flex 650 Toughened Epoxy and G/flex 655 Thickened Epoxy Adhesive are rubber-toughened systems that do well against impact and abrasion. They are great for coatings. G/flex 650 can be used to wet out lightweight fabrics. Some of our customers blend G/flex 650 with the 105 System to give more toughness to a laminate. If you want to do this, first measure and mix each system separately and then blend them together; that way, the resin-to-hardener ratios are correct.

G/Flex 655 is great when you want to apply a thicker coating or if you need to fill in a seam or gouge on a frequently abraded surface.

For more information on coating surfaces, see Tom Pawlak’s article “Improve Wooden Paddles with G/flex” in Epoxyworks 37.

Additives

Graphite Powder

423 Graphite Powder is a fine black powder that can be mixed with epoxy to produce a low-friction exterior coating with increased durability. The properties are a result of the graphite being exposed as the surface is worn by friction or intentional sanding. Otherwise, it would remain encapsulated in epoxy. While this additive is more frequently used to make a low-friction surface it can also increase durability against scuffing.

Use 423 Graphite Powder at 10% by volume in epoxy. While typically only used in the final coatings, the viscosity remains low enough that wetting out fabrics is easy. You can use it in combination with the reinforcement fabrics listed earlier.

Aluminum Powder

420 Aluminum Powder is finely milled aluminum you may add to epoxy at 5-10% by volume. It will increase the hardness and abrasion resistance of the coated surface. As with the 423 Graphite Powder, epoxy blended with 420 Aluminum Powder at 5-10% by volume remains low enough in viscosity to easily wet out fabrics we’ve mentioned.

Choose Your Combo

In summary, the right combination of fabrics, WEST SYSTEM Epoxies, and additives will go a long way in protecting surfaces from abrasion and impact. Common reinforcement fabrics are Kevlar, Dynel, Xynole, Innegra, Honeywell Spectra, and Fiberglass. Good epoxy systems and additives are the 105 System, G/Flex, 423 Graphite Powder, and 420 Aluminum Powder.

For further reading, “Ticonderoga: Testing for the Toughest Deck Coverings” in Epoxyworks 4 offers more information about abrasion and impact resistance. Spoiler alert: it includes the performance results of various laminates tested for impact.

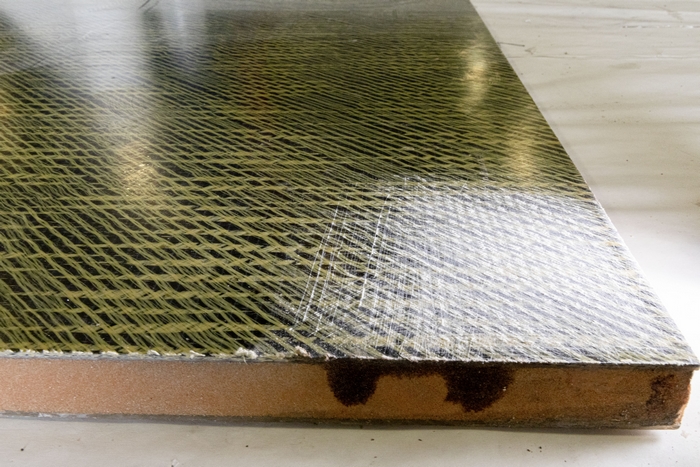

Sample of a carbon fiber/Kevlar laminate affected by abrasion. The left side is unaffected whereas the right side has been abraded. Note the fraying from the Kevlar fibers.