The age-old question regarding the order of operations when performing a fiberglass patch repair—does the largest or the smallest patch go down first?

By Avery Jorgensen—GBI Composite Materials Engineer

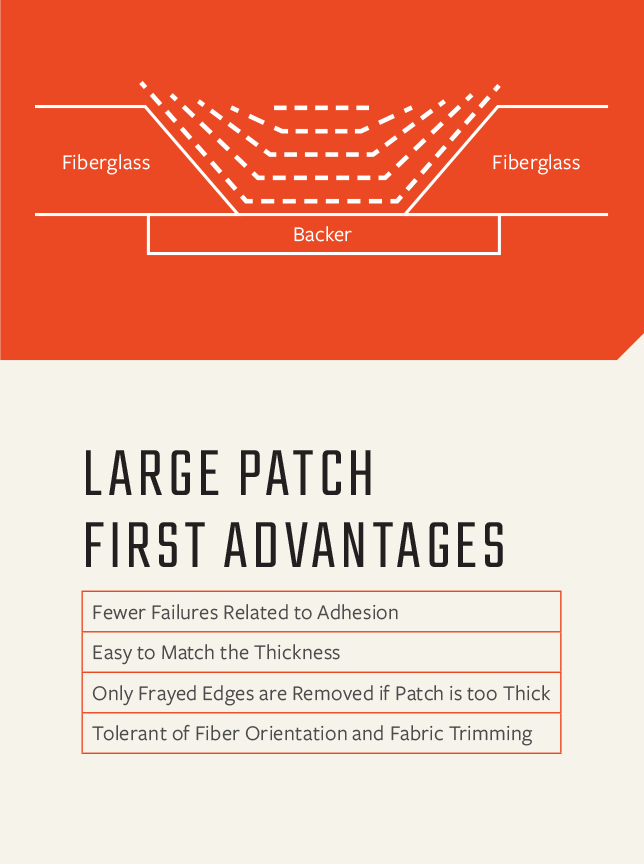

When performing a repair on a fiber reinforced laminate, which goes down first—The biggest patch or the smallest? Since this article is longer than a couple of sentences, it’s safe to assume the answer is a little bit complex. We at WEST SYSTEM® tend to recommend a marine repair technique, where the largest layer is applied first. We recommend this for two main reasons: adhesion and finishing. However, there are many advantages to each of these methods.

Adhesion

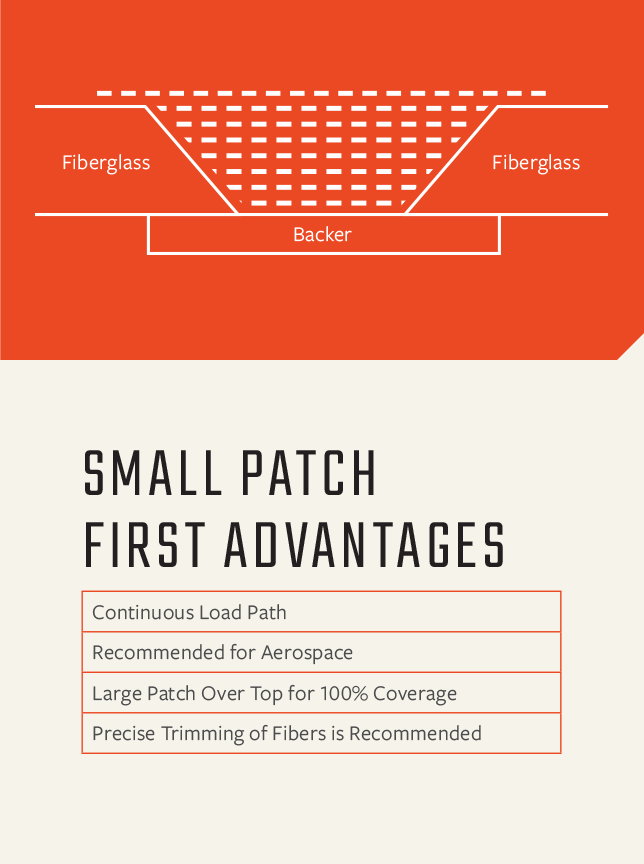

Placing the small patch down first is appealing because it is the method recommended for repairs in the aviation world. When performing a repair on an aircraft, it is extremely important to have a continuous load path running over the exterior of the repair. This requires the longest uninterrupted fibers (the large patch) to be on the exterior of the repair to carry that load. Also, all the fibers must be aligned with those surrounding the repair area, and each layer needs to be trimmed precisely. This kind of effort, while it may be beneficial, is generally unnecessary for marine repairs.

When a repair fails on a boat, the most common reason is that there was insufficient bond strength between the patch and the repair surface. When the largest patch is placed down first, then the most surface area is covered by the same piece of fabric. This creates a uniform bond between the patch and the repair surface. When placing the small patch down first, you are relying on a much smaller area for the adhesive strength of each layer.

Finishing

Placing the largest patch down first can also help improve the aesthetics of the final finish and the integrity. This is extremely important in marine repairs because the quality of a repair is often judged by the final finish. When performing a small patch first repair, the largest patch is the top-most surface to which any finishing is applied. This finishing process commonly includes a lot of sanding. That means you will be sanding into the largest amount of continuous fiberglass. Conversely, as you sand the surface where the largest patch is placed down first, the only area being sanded is the frayed edges of each layer. This allows for flush-sanded repairs with the most continuous fiberglass left intact.

Surface Fairing

Another significant factor is the work that goes into creating a fair surface. When the small patch is applied first, a lip is created where the patch overlaps the original surface. This lip is then translated up through the layers of the patch, creating a humped, uneven surface in your final repair. This means more sanding and fairing. The possible hump can be eliminated with precise fabric cutting and step scarfing. Step scarfing is the recommended aerospace repair technique that requires hours of precise routing to create steps for each layer of fabric to nest into. This reduces waviness, increases fiber alignment, and makes a flush surface. The problem with going down this route is the time and effort required to achieve results similar to those placing the large patch first.

Stiffness vs. Strength

When placing the smallest patch down first, the goal is to align the layers to create one uniform flow of stresses across the repair. Aligning the layers of your repair with the layers in the fiberglass you are repairing will give a more continuous strength profile. This is especially important if you are performing a step scarf. Though this does provide a slightly stronger composite in tensile strength, the increase is only slight.

For marine applications, the most important thing to remember is that most production boats are generally designed for stiffness. If they are stiff enough, they are usually strong enough. Being stiff prevents fatigue failures from repeated impacts, such as the waves on the hull of a boat. For repairs, we recommend using the same thickness of laminate and material as was removed to ensure enough stiffness. Most marine structures are made with fiberglass, but we recommend repairing fiberglass with fiberglass and carbon fiber with carbon fiber. Having the same thickness of laminate and laminate material (the repair and the surrounding area) will prevent sudden changes in flexibility. This prevents stress concentration points. Soft or hard spots are a major concern because they will ultimately cause failure.

Fiber orientation will also be a factor in the strength and stiffness of the repair; however, adhesion will most often be the limiting factor on a boat.

Conclusion

The age-old question of which patch goes down first —the big one or the small one —has many possible answers. If you are looking for the easiest application method, with the least likely chance to pop off, I recommend placing the largest patch first. This allows you to achieve consistent adhesion across the entire repair surface. If you are looking for a slightly stronger repair that may be more difficult, the smallest first is the choice for you.